The DTF Gang Sheet Builder tool streamlines complex design planning for custom printing on textiles, minimizing waste and maximizing material usage. It automates layout creation, ensures precise cutting and alignment, saves time, and enables users without design skills to produce professional DTF gang sheets for high-quality custom tee designs.

“Unleash precision in your print production with a DTF (Direct to Final) Gang Sheet Builder Tool. This article guides you through the intricacies of mastering accurate margins, a key aspect often overlooked but vital for high-quality prints.

We’ll explore the concept of DTF gang sheets and how an automated builder tool revolutionizes margin setting. From understanding fundamental principles to providing a step-by-step creation process, this guide ensures you leverage the power of technology for flawless results.”

- Understanding DTF Gang Sheets for Precise Margins

- Benefits of Using an Automated Builder Tool

- Creating Accurate Sheets: Step-by-Step Guide

Understanding DTF Gang Sheets for Precise Margins

Understanding DTF Gang Sheets is key to achieving precise margins when printing on textiles like DTF for t-shirts and creating custom items such as direct to film personalized hoodies. A DTF Gang Sheet Builder Tool offers a streamlined way to organize and plan these intricate designs. By using this tool, designers and print professionals can efficiently create layouts that maximize the use of material while ensuring minimal waste. This, in turn, leads to cost savings and higher profitability.

The DTF Gang Sheet Builder allows for precise placement of designs on a sheet, taking into account various factors like cutting lines, trim margins, and the final product’s shape. This meticulous approach is particularly beneficial when dealing with complex artwork or multiple design variations. It enables printers to produce high-quality, personalized items with consistent accuracy, meeting the growing demand for customized apparel and merchandise.

Benefits of Using an Automated Builder Tool

Using an automated DTF Gang Sheet Builder tool offers numerous advantages for businesses and individuals looking to streamline their custom printing process, especially when it comes to DTF for Custom Graphic Tees. Firstly, it significantly reduces human error, ensuring precise cutting and layout designs that are consistently accurate. This precision is vital in achieving crisp, high-quality prints on various materials, from fabric to wood.

An efficient tool like a DTF Gang Sheet Builder also saves time and enhances productivity. It automates repetitive tasks, allowing users to focus on creative aspects. With its user-friendly interface, even those without design expertise can create professional layouts. Additionally, these tools often provide real-time previews, enabling quick adjustments before final printing, ensuring the best DTF meaning is maintained throughout the process.

Creating Accurate Sheets: Step-by-Step Guide

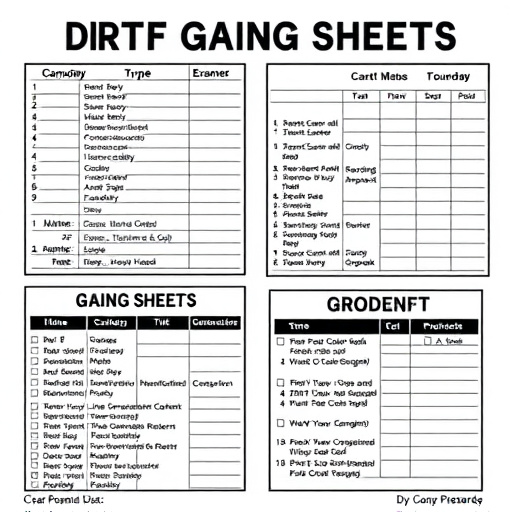

Creating accurate DTF Gang Sheets is a straightforward process when using the right tool—the DTF Gang Sheet Builder. Here’s a step-by-step guide to help you achieve precise margins and high-quality prints for your custom designs:

1. Select Your Design: Start by choosing the artwork or design that you want to print. Ensure it’s in the correct file format (like SVG, JPEG, or PNG) and has a resolution suitable for DTF printing, typically 300 DPI or higher. For light fabric printing like personalized hoodies using direct to film (DTF) printers, this attention to detail is even more crucial as subtle variations can affect the final product.

2. Choose Your Layout: The DTF Gang Sheet Builder allows you to customize the layout to fit your specific needs. Decide on the number of designs per sheet and arrange them accordingly. This step ensures efficient use of space and precise alignment during printing, minimizing waste and maximizing productivity.

3. Set Margins and Bleed: Accurate margins are vital for successful DTF printing. Set the appropriate margin values within the builder tool. Additionally, consider adding a bleed area around your design, especially if using full-bleed printing techniques. This step prevents white borders from appearing on your final products after cutting.

4. Preview and Adjust: Before finalizing, use the preview feature to check that everything is positioned correctly. Ensure designs fit within their designated areas without overlapping or extending beyond the sheet’s boundaries. Making adjustments at this stage saves time and guarantees a flawless print job.

5. Export and Print: Once satisfied with your layout, export the DTF Gang Sheet as a PDF or any other supported format recommended by your printer manufacturer. Then, load it onto your DTF printer and initiate the printing process.

A DTF Gang Sheet Builder tool revolutionizes the way you create precise margin calculations, enhancing efficiency and accuracy in your production processes. By automating the sheet generation process, this technology ensures that every detail is accounted for, from material specifications to cutting layouts. With a simple step-by-step guide, even non-experts can create accurate sheets, saving time and resources. Embrace this innovative approach to gain a competitive edge in manufacturing and streamline your workflow with the power of an automated DTF Gang Sheet Builder.